Quick, Efficient and Precise Cutting

Waterjet Material Cutting

Centerline Machine in central Wisconsin is a leader in abrasive waterjet material cutting. Waterjet cutting is one of the most versatile cutting methods available.

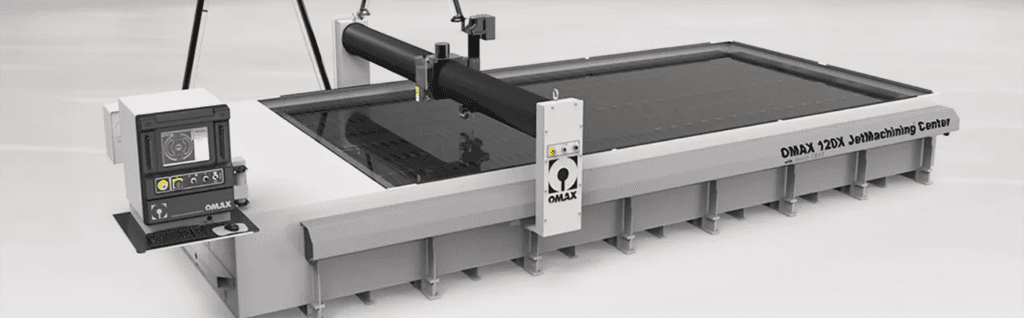

Our OMAX 120X Precision JetMachining Center is one of the largest and most capable waterjet machines in the region. It is ideal for multiple-part projects or large-scale part production, and can cut a wide range of materials and thicknesses, from metals and composites to glass and plastics. Its linear position accuracy is ±0.001″ (±0.025 mm).

In addition, we have the smaller OMAX 55100 Precision JetMachining Center, which allows our highly-skilled operators to match capabilities to requirements for the most cost-effective water jet cutting solution. It has ±0.001 (±0.025 mm) linear position accuracy.

Waterjet material cutting is a unique and powerful technology that offers the following benefits:

- Shapes and patterns can be cut from virtually any material including ferrous and non-ferrous metals, alloy metals, copper, brass, plastics and fibrous materials

- No heat-affected zones (HAZ) or mechanical stresses are created during cutting – thus no warping, hardening, or discoloration occurs

- Material is used efficiently

- Smooth edge cutting reduces the need for secondary operations

- No dust or fumes are created

Waterjet Cutting Wisconsin

From our location in central Wisconsin, Centerline Machine serves manufacturers through the state and beyond. Contact us to discuss projects that could benefit from the precision offered by waterjet cutting in Wisconsin.

Contact Us

Have a question about our waterjet cutting? Use our quick contact form below. Or, call us in central Wisconsin location at 715-258-5229 or email us at quotes@centerlinemachine.com.