Quick, Efficient and Precise Cutting

Waterjet Material Cutting

Centerline Machine in central Wisconsin is a leader in abrasive waterjet material cutting.

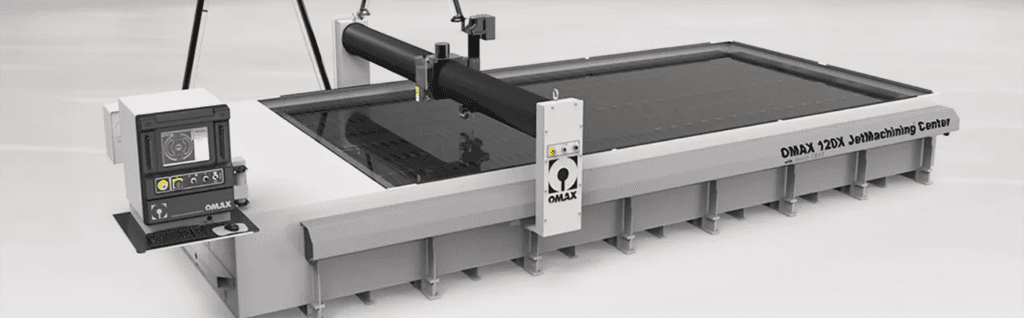

Our OMAX 120X Precision JetMachining Center is one of the largest and most capable waterjet machines in the region. It is ideal for multiple-part projects or large-scale part production, and can cut a wide range of materials and thicknesses, from metals and composites to glass and plastics. Its linear position accuracy is ±0.001″ (±0.025 mm).

In addition, we have the smaller OMAX 55100 Precision JetMachining Center, which allows our highly-skilled operators to match capabilities to requirements for the most cost-effective water jet cutting solution. It has ±0.001 (±0.025 mm) linear position accuracy.

Waterjet material cutting is a unique and powerful technology that offers the following benefits:

- Shapes and patterns can be cut from virtually any material including ferrous and non-ferrous metals, alloy metals, copper, brass, plastics and fibrous materials

- No heat-affected zones or mechanical stresses are created during cutting

- Material is used efficiently

- Smooth edge cutting reduces the need for secondary operations

Contact Us

Have a question about our waterjet cutting? Use our quick contact form below. Or, call us in central Wisconsin location at 715-258-5229 or email us at quotes@centerlinemachine.com.